Recoveries of 97% Gold, 92% Zinc and 85% Copper to High Quality Concentrates

Vancouver, BC – June 22, 2022 – HighGold Mining Inc. (TSX-V:HIGH, OTCQX:HGGOF) (“HighGold” or the “Company”) is very pleased to announce positive metallurgical test results for the Johnson Tract polymetallic Gold Project (“Johnson Tract”, “JT” or the “Project”) in Southcentral Alaska, USA. The Project hosts the high-grade Au-Zn-Cu-Pb-Ag JT Deposit with a 0.75moz gold equivalent (“AuEq”) indicated resource at 10.9 g/t AuEq and a 0.13moz AuEq inferred resource at 7.1 g/t AuEq. An updated and expanded mineral resource estimation for the JT Deposit is expected to be delivered before the end of the second quarter of 2022.

Highlights of Metallurgical Test Results

The polymetallic (Au-Zn-Cu-Pb-Ag) JT Deposit exhibits an excellent response using conventional metallurgical techniques. Locked cycle flotation tests yielded very high-quality copper, zinc, lead and gold concentrates produced at a coarse primary grind with very good metal recoveries, low impurities and negligible penalty elements. Highlights include:

- Gold recovery of 97.2% combined total of payable gold to concentrates and leaching of tails

- Zinc recovery of 92.3% to a concentrate grading 52.6% zinc

- Copper recovery of 84.5% to a concentrate grading 30.6% copper

- Lead recovery of 72.4% to a concentrate grading 62.1% lead

- Gold pyrite concentrate grading 64.3 g/t gold

- Coarse primary grind size of 125 microns

“We are very pleased with these metallurgical results, which demonstrate excellent metal recoveries to highly-quality concentrate products,” commented President and CEO Darwin Green. “Metallurgy is critically important to understanding the potential economics of a mineral project and these new results, which corroborate and enhance decades-old historic data, are an important step in de-risking the JT Project and laying the foundation for future engineering and economic studies. In addition to producing gold-enriched base metal concentrates that are highly attractive for global smelting market, the program was also successful in producing a saleable high-grade gold concentrate. The ability to produce a separate gold (pyrite) concentrate provides processing optionality with the added environmental benefit of generating tails that contain very low-sulphide content.” Please CLICK HERE to hear additional commentary by CEO Darwin Green.

Test Program Details

The metallurgical test program (the “Program”) was completed by Blue Coast Research Ltd. (“BCR”), a leading metallurgical testing and consulting firm based in British Columbia. The testwork was completed on a master composite sample (“Master Composite”) prepared from approximately 180 kg of ½ sawn HQ drill core from two dedicated holes, JT21-125 and JT21-134, drilled into the JT Deposit mineral resource in 2021.Sampled intervals included a blend from the upper and lower portions of the JT Deposit representative of the dominant mineralization styles present within the deposit. The Master Composite has a head grade of 11.85 g/t gold, 6.2 g/t silver, 0.52% copper, 5.13% zinc, and 1.27% lead.

The Program included mineralogical analysis, comminution testwork, flotation optimization testwork, locked cycle testwork, cyanidation of rougher tails and cleaner concentrates for global gold recovery, and follow-up mineralogical analysis of concentrates and tailings for deleterious elements.

Discussion of Test Program Results

Mineralogy and Comminution

Mineralogical analysis of the Master Composite showed that primary sulphide minerals are sphalerite, pyrite, chalcopyrite and galena. Pyrite, sphalerite and chalcopyrite all show very good liberation, with galena showing moderate liberation. Comminution testwork conducted on the Master Composite yielded the following results:

- Bond Ball Work Index of 16.6 kWh/tonne indicating the sample is hard

- Bond Abrasion index testing results indicated the sample is moderately abrasive

- SMC testwork showed that this sample was soft with respect to impact

Flotation

Flotation optimization was conducted on the Master Composite through a series of batch rougher and cleaner tests under a variety of conditions followed by a single locked cycle flotation test. The parameters explored included: i) primary grind size; ii) lead and zinc depressants; iii) lead regrind; iv) gold/pyrite circuit; and v) an MF2 (Mill-Float x 2) flowsheet. The best flotation conditions were then applied to the locked cycle test.

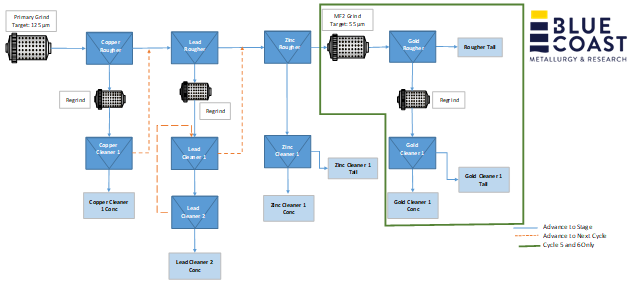

The locked cycle test was conducted as a standard six-cycle test; the flowsheet is presented in Figure 1. The copper, lead and zinc circuits were conducted on all six cycles, and the gold circuit was added to cycle 6. A coarse primary grind of 125 microns was utilized, with flotation of a copper rougher concentrate reground and cleaned once, followed by flotation of a lead rougher concentrate reground and cleaned twice. The zinc rougher concentrate was cleaned once with no regrind. The gold circuit consisted of a secondary grind of the zinc rougher tails (MF2 flowsheet), followed by gold rougher, concentrate regrind, and gold cleaner float. Table 1 shows the projected metallurgy for the locked cycle test.

All concentrates met target grades for the metal of interest and recoveries were overall very good. Gold concentration is at payable levels for all concentrate products, including the zinc concentrate, with a majority reporting to the copper, lead and pyrite concentrates where pay-ability is highest. Low levels of deleterious elements and impurities were detected in the final concentrates and no penalties are expected for any of the concentrate products based on current smelter contract standards (Table 2).

Leach Tests

Separate cyanidation leach tests were performed to evaluate different processing scenarios, including a) cyanidation of rougher tails in the absence of floating a gold concentrate, b) cyanidation of rougher tails generated after producing a gold concentrate, and c) cyanidation of the gold concentrate itself. Gold recovery results for the three tests are presented in Table 3.

Total Payable Gold Recovery

Estimated total payable gold recovery is 97.2% (Table 4). For the purpose of calculating total payable gold recovery, it is assumed that the gold concentrate will be sold (not leached) and all final tails products (Au Rougher tails plus Zn and Au cleaner tails) will be combined and leached together at 81% recovery.

Table 1: LCT-1 Projected Metallurgy

| Product | Assays | % Distribution | ||||||||||

| Au (g/t) |

Ag (g/t) |

Cu (%) |

Pb (%) |

Zn (%) |

S (%) |

Au | Ag | Cu | Pb | Zn | S | |

| Cu Concentrate | 276 | 71 | 30.6 | 2.11 | 3.94 | 33.4 | 32.7 | 15.3 | 84.5 | 2.4 | 1.1 | 8.7 |

| Pb Concentrate | 220 | 95 | 1.42 | 62.1 | 15.1 | 18.1 | 26.9 | 21.1 | 4.0 | 72.4 | 4.3 | 4.9 |

| Zn Concentrate | 10.4 | 26 | 0.31 | 2.85 | 52.6 | 31.9 | 7.8 | 35.5 | 5.5 | 20.4 | 92.3 | 52.7 |

| Zn Cleaner Tail | 7.64 | 7 | 0.21 | 0.35 | 0.77 | 9.15 | 1.6 | 2.5 | 1.1 | 0.7 | 0.4 | 4.3 |

| Au Concentrate | 64.3 | 24 | 0.38 | 0.70 | 1.52 | 33.3 | 18.5 | 12.4 | 2.6 | 1.9 | 1.0 | 21.1 |

| Au Cleaner Tail | 2.17 | 2 | 0.04 | 0.08 | 0.10 | 1.49 | 1.4 | 2.2 | 0.6 | 0.5 | 0.1 | 2.1 |

| Rougher Tail | 1.85 | 1 | 0.01 | 0.03 | 0.05 | 0.48 | 11.0 | 11.0 | 1.8 | 1.7 | 0.7 | 6.2 |

| Calc. Head | 12.4 | 7 | 0.53 | 1.30 | 5.29 | 5.62 | 100 | 100 | 100 | 100 | 100 | 100 |

Table 2: LCT-1 Concentrate Deleterious Element Content

| Product | As | Bi | Cd | Hg | Mn | Sb | Se |

| (ppm) | (ppm) | (pm) | (ppm) | (ppm) | (ppm) | (ppm) | |

| Cu Concentrate | 63 | <2 | 162 | 0.28 | 71 | 13 | 228 |

| Zn Concentrate | 133 | <2 | 2218 | 0.99 | 411 | 39 | 93 |

| Pb Concentrate | 27 | <2 | 611 | 0.49 | 64 | 51 | 134 |

| Au Concentrate | 903 | <2 | 47 | 0.31 | 1029 | 73 | 82 |

Concentrates are considered ‘clean’ by industry standard with deleterious elements well below smelter penalty levels

Table 3: Cyanidation Leach Test Results

| Product | Au Recovery (48hrs) | Ag Recovery (48hrs) |

|

Rougher Tails absent production of a gold concentrate |

82.4% | 47.1% |

|

Rougher Tails generatedfrom gold concentrate |

81.0% | NA |

|

Gold Concentrate |

93.0% | 49.5% |

Table 4: Total Payable Gold Recovery

| Product | Au (g/t) | Distribution (%) |

| Cu Concentrate | 276 | 32.7 |

| Pb Concentrate | 220 | 26.9 |

| Zn Concentrate | 10.4 | 7.8 |

| Au Concentrate | 64.3 | 18.5 |

| Combined Rougher and Cleaner Tails (CN 81%) | 1.85 to 7.64 | 11.3 |

| TOTAL GOLD RECOVERY | 97.2% |

Figure 1 – JT Deposit - LCT-1 Flowsheet

Additional Test Work and Opportunities

Additional metallurgical test work is ongoing to assess JT Deposit variability including the evaluation of other mineralization styles such as the footwall copper zone. Several opportunities for further optimization and flowsheet refinement exist and will be evaluated in future studies.

2022 Exploration Program

The Company recently announced plans for a US$9 million summer exploration program for the Project (See Company press release dated May 31, 2022) which includes a minimum of 13,000 meters of diamond drilling with two drill rigs, geological mapping, prospecting and geochemical sampling programs, airborne drone-magnetic surveying, the commissioning of a new onsite sample preparation facility to reduce assay turnaround times, and preliminary engineering and baseline studies. One third of the planned drilling will focus on infill and step-out drilling on the JT Deposit, while the remaining two thirds will follow-up on the new high-grade DC Prospect Discovery (See Company press release dated October 6, 2021) and other new regional prospects.

About the Johnson Tract Gold Project

Johnson Tract is a poly-metallic (gold, copper, zinc, silver, lead) project located near tidewater, 125 miles (200 kilometers) southwest of Anchorage, Alaska, USA. The 21,000-acre property includes the high-grade JT Deposit and at least nine (9) other mineral prospects over a 12-kilometer strike length. HighGold acquired the Project through a lease agreement with Cook Inlet Region, Inc. (“CIRI”), one of 12 land-based Alaska Native regional corporations created by the Alaska Native Claims Settlement Act of 1971. CIRI is owned by more than 9,100 shareholders who are primarily of Alaska Native descent.

Mineralization at Johnson Tract occurs in Jurassic-age intermediate volcaniclastic rocks and is characterized as epithermal-type with submarine volcanogenic attributes. The JT Deposit is a thick, steeply dipping silicified body (20m to 50m average true thickness) that contains a stockwork of quartz-sulphide veinlets and brecciation, cutting through and surrounded by a widespread zone of anhydrite alteration. The Footwall Copper Zone is located structurally and stratigraphically below JT Deposit and is characterized by copper-silver rich mineralization.

The JT Deposit hosts an Indicated Resource of 2.14 Mt grading 10.93 g/t AuEq comprised of 6.07 g/t Au, 5.8 g/t Ag, 0.57% Cu, 0.80% Pb and 5.85% Zn. The Inferred Resource of 0.58 Mt grading 7.16 g/t AuEq is comprised of 2.05 g/t Au, 8.7 g/t Ag, 0.54% Cu, 0.33% Pb, and 6.67% Zn. Reported mineral resources are based on drill holes completed to the end of 2019. Approximately 27,000 meters of new drilling have subsequently been completed and a new resource estimate is anticipated Q2 2022. For additional details see NI 43-101 Technical Report titled “Updated Technical Report for the Johnson Tract Project, Alaska” dated August 9, 2021 authored by Ray C. Brown, CPG, and James N. Gray, P.Geo. Gold Equivalent is based on assumed metal prices and 90% recovery for Au, Ag, Cu, Pb, and Zn. Assumed metal prices for the Resource are US$1350/oz for gold (Au), US$16/oz for silver (Ag), US$2.80/lb for copper (Cu), US$1.00/lb for lead (Pb), and US$1.20/lb for zinc (Zn) and are based on nominal 3-year trailing averages as of April 1, 2020. Metallurgical testing has indicated that excellent gold and base metal recoveries and marketable concentrates can be expected.

Prior to HighGold, the Project was last explored in the mid-1990s by a mid-tier mining company that evaluated direct shipping material from Johnson to the Premier Mill near Stewart, British Columbia.

About HighGold

HighGold is a well-funded mineral exploration company focused on high-grade gold projects located in North America. HighGold’s flagship asset is the high-grade Johnson Tract Gold (Zn-Cu) Project located in Southcentral Alaska, USA. The Company also controls a portfolio of quality gold projects in the greater Timmins gold camp, Ontario, Canada that includes the Munro-Croesus Gold property, which is renowned for its high-grade mineralization, and the large Golden Mile and Timmins South properties. HighGold’s experienced Board and senior management team, are committed to creating shareholder value through the discovery process, careful allocation of capital, and environmentally/socially responsible mineral exploration.

Qualified Person and Quality Assurance

Ian Cunningham-Dunlop, P.Eng., Senior VP Exploration for HighGold Mining Inc. and a qualified person (“QP”) as defined by Canadian National Instrument 43-101, has reviewed and approved the technical information contained in this release.

On Behalf of HighGold Mining Inc.

“Darwin Green”

President & CEO

For further information, please visit the HighGold Mining Inc. website at www.highgoldmining.com, or contact:

Darwin Green, President & CEO or Naomi Nemeth, VP Investor Relations

Phone: 1-604-629-1165 or North American toll-free 1-855-629-1165

Email: moc.gninimdloghgih@noitamrofni.

Website: www.highgoldmining.com

Twitter: @HighgoldMining

The Company has a robust QAQC program that includes the insertion of blanks, standards and duplicates.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward looking statements: This news release includes certain “forward-looking information” within the meaning of Canadian securities legislation and "forward-looking statements" within the meaning of the United States Private Securities Litigation Reform Act of 1995 (collectively “forward looking statements”). Forward-looking statements include predictions, projections and forecasts and are often, but not always, identified by the use of words such as “seek”, “anticipate”, “believe”, “plan”, “estimate”, “forecast”, “expect”, “potential”, “project”, “target”, “schedule”, “budget” and “intend” and statements that an event or result “may”, “will”, “should”, “could” or “might” occur or be achieved and other similar expressions and includes the negatives thereof. All statements other than statements of historical fact included in this release, including, without limitation, statements regarding the Company’s 2022 exploration plans and potential future engineering studies are forward-looking statements that involve various risks and uncertainties. There can be no assurance that such statements will prove to be accurate and actual results and future events could differ materially from those anticipated in such statements. Forward-looking statements are based on a number of material factors and assumptions. Important factors that could cause actual results to differ materially from Company’s expectations include actual exploration results, changes in project parameters as plans continue to be refined, results of future resource estimates, future metal prices, availability of capital and financing on acceptable terms, general economic, market or business conditions, uninsured risks, regulatory changes, defects in title, availability of personnel, materials and equipment on a timely basis, accidents or equipment breakdowns, delays in receiving government approvals, unanticipated environmental impacts on operations and costs to remedy same, and other exploration or other risks detailed herein and from time to time in the filings made by the Company with securities regulators. Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ from those described in forward-looking statements, there may be other factors that cause such actions, events or results to differ materially from those anticipated. There can be no assurance that forward-looking statements will prove to be accurate and accordingly readers are cautioned not to place undue reliance on forward-looking statements.